Intra NVH Analysis

Production Gear NVH Analysis & Quality System

The Ghost Order Problem

With the new demands for “Ultra Quiet Transmissions” and the corresponding relentless reduction in Gear Tolerances, manufacturers are coming to the realisation that the traditional methods of Inspection to control gear processes no longer provide an assured pathway to final product quality and more seriously, Gear Noise.

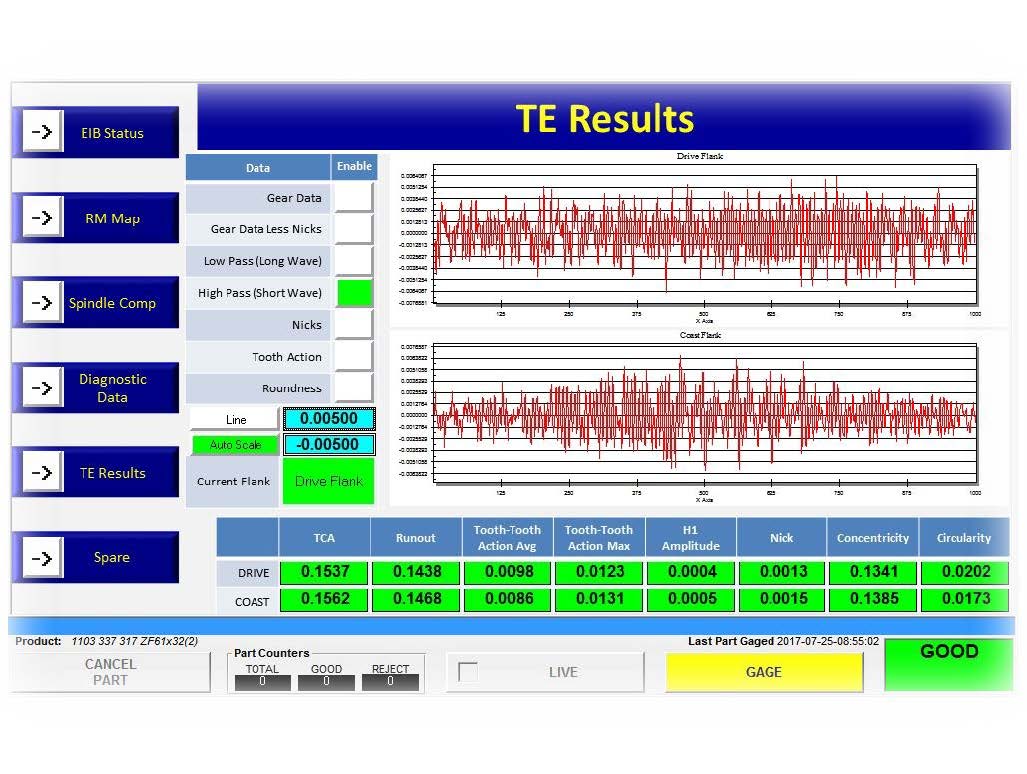

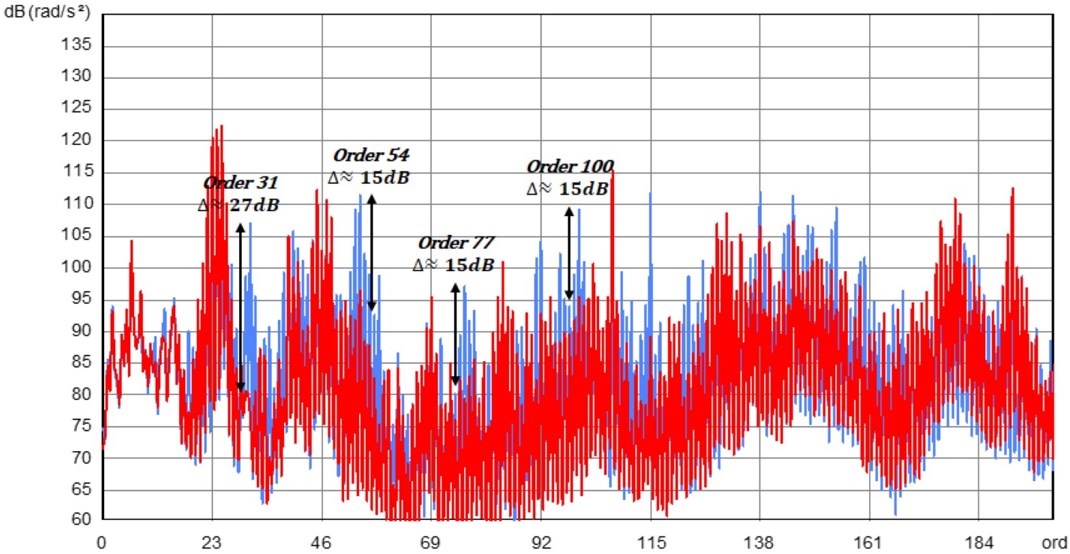

First there needs to be a understanding of the problem. Ghost Order Noise is generally the result of modulations being imprinted into the active gear surfaces, Profile and/or Gear Flanks. These modulations or ripples are generally present on all the gear teeth which is how the vibration energy is generated & amplified leading to the Transmission Final Test stand failure.

INTRA recognised this problem 15 years ago with the advent of Hard Finishing of gear teeth, and started evaluating the technologies required to detect these failures.

Since then, INTRA have pioneered a proven, new, cutting-edge production inspection system capable of detecting and identifying failure modes on single gears or gear pairs which, until now could not be detected until assembled in the transmission.

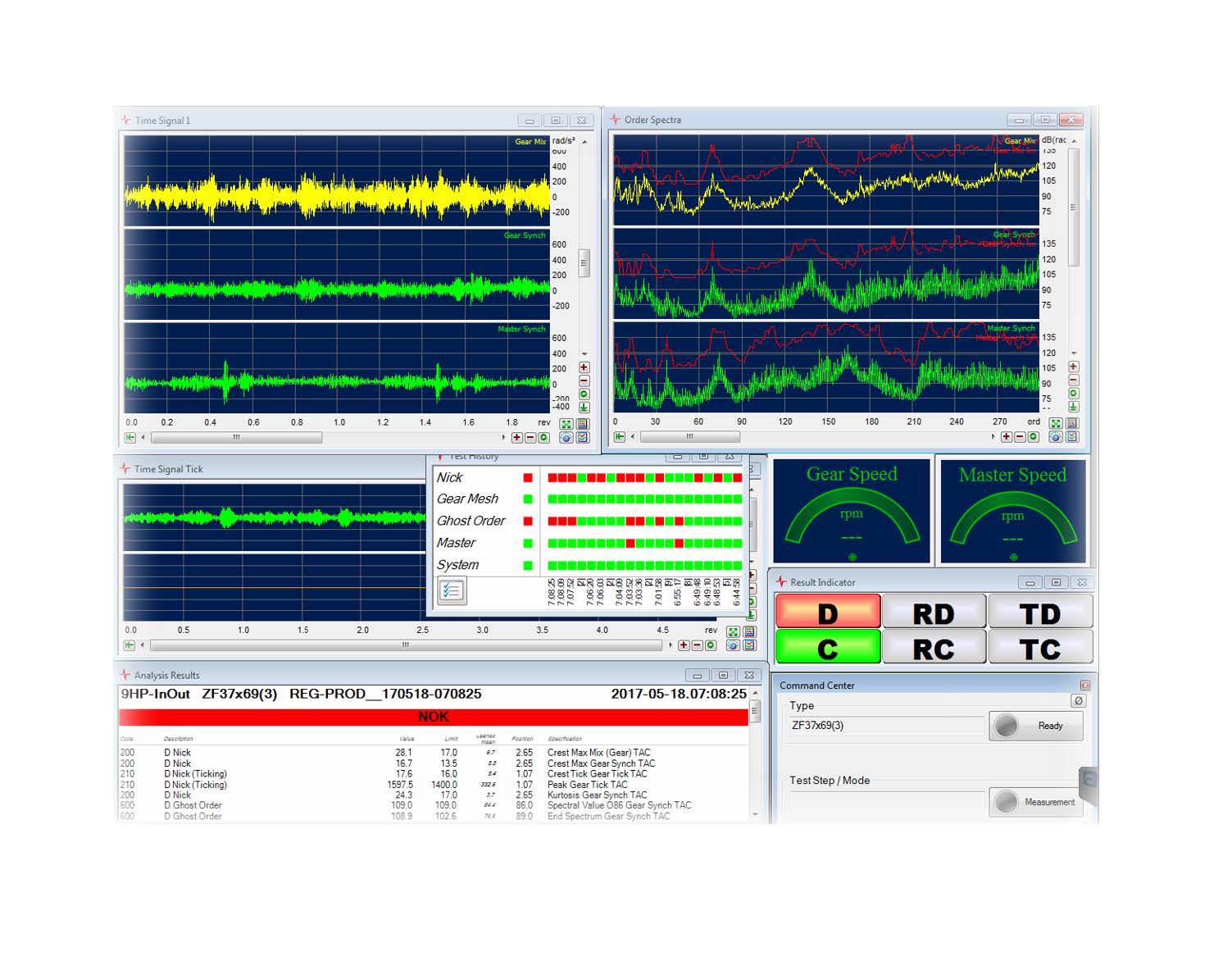

INTRA also offers the option of expanding the measurement suite to include traditional Transmission Error gauging for low order error evaluation.

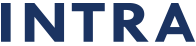

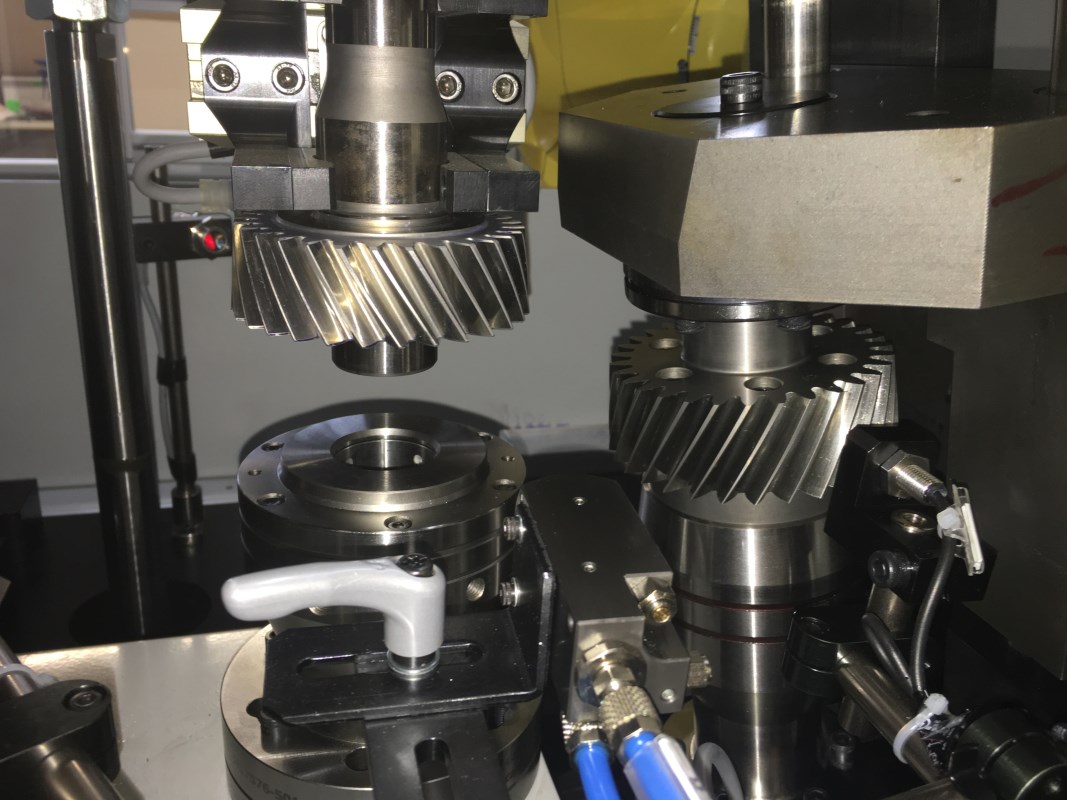

The INTRA NVH Gear Analyser achieves in seconds what was previously counted in hours using traditional analytical methods and is ideally suited to the challenges presented by the production environment.

This new rapid evaluation of individual gears offers a marked step forward in the gear manufacturing world. It offers direct feedback and feedforward data to the manufacturing process and the transmission assembly respectively as well reporting OK or Reject.

This new rapid evaluation of individual gears offers a marked step forward in the gear manufacturing world. It offers direct feedback and feedforward data to the manufacturing process and the transmission assembly respectively as well reporting OK or Reject.

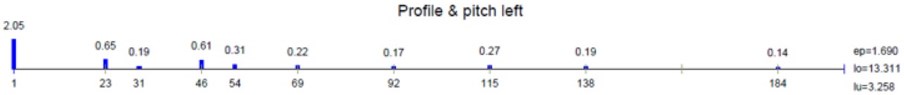

The analysis is capable of separating the gear mesh frequencies of each gear in the meshing pair and generating order spectra for both. Other methods of Analysis are available such as Gear Mesh Loudness, modulation and advanced Nick Analysis with position.

NVH Gear Analysis System

As a leading world supplier of Production Gear Inspection Systems, INTRA offers a flexible solution, allowing for seamless automated integration into existing Manufacturing Production Lines, as well as self-contained stand alone semi-automatic systems for Laboratory use, the choice is yours.

The system is accommodating of any external parallel axis gears including:

- Spur Gears

- Helical Gears

- Shafted gears

- Shallow Angle ‘Beveloid’ Gears

The individual sets of Gear Flank data collected from the Gear Test are translated to an Order Spectrum. The results of this data has been proven many times to directly correlate to the End Of Line Transmission Test Stands as well as advanced Analysis reports generated by analytical lab equipment.

General Machine Specifications

| Utilities | |

| Machine Electrical Power | 400/460 VAC, 3 Phase + PE, 50/60Hz, FLC 40 Amps |

| Machine Pneumatic Supply | 5 Bar Minimum (70 PSI) |

| Transmission Fluid Test Lubrication | 4 Litre Container – Low Level Monitored |

| Operating Parameters | |

| NC Axis – Master Spindle | 60mm Travel + 10mm Overtravel |

| Maximum Spindle Velocity | 2000 Rpm |

| Maximum Spindle Torque | 34 Nm Peak |

| Operating Test Modes | |

| Constant Speed, Constant Torque | |

| Ramped Speed Constant Torque | |

| Constant Speed, Ramped Torque | |

| Same Flank, 2nd Pass Test | |

| Operating Parameters | |

| Hardwired Safety Circuits | EN 954 - Category 4 - CE / UL / CSA Compliant |

| Control Systems | Siemens Based |

| Pneumatic Systems | Festo Based |

| Component Sizes | |

| Gear Testing Centre Distance | Variable 125-185 mm – Resolution 0.001mm |

| Gear Facewidth | Up to 60 mm Typ |

| Gear Shaft Length (tooling dependant) | Up to 250 mm |

(734) 326 7030

HEADQUARTERS

885 Manufacturers Drive

Westland, Michigan 48186 MAP

© 2020 Intra Corporation.